The actualization of collaborative robots has created new paradigms for automated automation. Automated apprentice deployments commonly appropriate massive basic investment, teams of engineering and programming specialists and abounding months of advance time.

Some all-embracing automated apprentice deployments can booty years and tens of millions of dollars to complete. That’s afore factoring in advancing maintenance, programming and abutment costs.

Cobots afflicted that by accouterment manufacturers with a applicable another to acceptable automation’s complex, costly, and time-consuming “all-or-nothing” access in the anatomy of a modernized, human-friendly automation paradigm. They can be acclimated in abounding industries, such as electronics manufacturing, metal artifact and others. Collaborative robots, beneath big-ticket and easier to arrange than acceptable robotics (even by those after apprentice experience), accept broadcast use of automation to bags of small- and medium-sized businesses.

Additionally, clashing acceptable robots, cobots can be cautiously deployed in the aforementioned workspace as bodies after the charge for all-encompassing assurance angry and guarding, afterward a accident assessment. With floorspace at a exceptional in best automated and accomplishment settings, cobots’ baby footprint, assurance appearance and cage-free deployment possibilities add to the fast-growing all-around abode of cobot technology.

Figure 1: “Cobots gave us the befalling to grow, expand, actualize added jobs, and move our best admired resources— our animal resources—into new projects, area the adeptness was best needed,” said Aldo Albieri, operations administrator at thyssenkrupp Bilstein’s bulb in Hamilton, Ohio, area UR10 cobots from Universal Robots handle apparatus tending, assembly, and artefact inspection. “If we relied alone on hiring new people, we would never be able to aggrandize three times the admeasurement we originally had.” Courtesy: Universal Robots

Cobots can be deployed abutting to bodies after appropriate angry (following a accident assessment) and are accessible to program. They additionally can bear massive improvements in ergonomics for absolute workers by demography over the repetitive, able tasks that advance to ache and injury. This frees animal workers to focus on higher-value tasks. Cobots additionally accommodate 24/7 availability and constant achievement which leads to bigger affection outcomes compared to tasks performed manually.

The curtailment of accessible activity is a abiding claiming for the accomplishment area and a claiming that has been affronted by the COVID-19 pandemic; 62.4% of respondents to a National Association of Manufacturers (NAM) analysis in December 2020 articular alluring and appliance a affection workforce as their primary business challenge.

Cobots are an able way for manufacturers to abode these activity gaps, enabling companies to access accumulation and throughput and advance quality, admitting advancing activity bazaar shortfalls. As it becomes added difficult to acquisition activity for absolute handling, welding, baby genitalia assembly, and computer after ascendancy (CNC) apparatus tending, and adjustment tasks, cobots accept been acrimonious up the slack.

Valued at about $674.9. actor in 2020, the all-around cobot bazaar is accepted to access at a admixture anniversary advance amount (CAGR) of 28% through 2025, according to bazaar analysts BIS Research. Similarly, Emergen Analysis predicts cobot sales will ascend to $9.3 billion by 2027, up from about $700 actor in 2019. Meanwhile, numbers from the All-embracing Federation of Robotics (IFR) acknowledge cobots are the fastest-growing articulation of the automated apprentice market.

Figure 2: After assuming a accident assessment, Seattle, Wash.-based aerospace architect Tool Gauge deployed a UR5 cobot in a plastics accumulation and dispensing appliance that involves abutting human-robot collaboration. The cobot’s force attached assurance arrangement ensures that it will automatically stop operating if it encounters an obstacle. Courtesy: Universal Robots

The aboriginal adopters of cobot technology in the backward 2000s were affairs into several new annual such as:

So far, the aboriginal cobot adopters accept been accurate right. Cobots accept approved their annual above tens of bags of acknowledged deployments in the automotive, manufacturing, pharma and electronics sectors and on applications as assorted as apparatus tending, assembly, finishing, inspection, packaging & palletizing. Today, cobots annual for about 5% of the all-around automated apprentice market. Analysis from Interact Analysis predicts that will access to about 30% by 2027.

With cobots on the border of activity mainstream, it’s time to analyze some of the key questions that can advice drive a acknowledged cobot deployment.

Due to their ease-of-use and baby footprint, cobots are alluringly ill-fitted to do-it-yourself implementations. If your appliance is a simple one –such as a pick-and-place operation—then companies should feel assured in their adeptness to handle the deployment in-house. DIY deployments are appreciably cheaper than those that crave affiliation specialists, which is a aloft allure for baby companies with bound automation budgets.

Keep in apperception there are ample variations in the abundance and affection of the educational assets provided by altered cobot makers. Decidedly for those with little or no antecedent robotics experience, it’s capital to analyze cobot brands that accommodate the online training, apprenticeship and abutment appropriate to apparatus a cobot in-house.

For added circuitous applications, or for any reason, the centralized capabilities don’t extend to a abounding deployment. Companies charge to accept amid three types of integration.

Every appliance is altered and presents its own challenges. Some risks are inherent to the process, such as arc welding. Other risks appear from the accession of added complexity, such as back a eyes arrangement is added to a cobot cell. The ambiance additionally can present risks, decidedly in affiliation to damp and temperature levels. Factors such as how abutting to best burden you accomplish your cobot can appulse on the lifespan of the equipment. Ask your cobot architect for an appliance accident agenda that can advice you accomplish an abreast appraisal of these factors.

Risk assessments are an binding allotment of the cobot deployment process. For advice on commutual a accident assessment, appointment the A3 Robotics website (part of the Association for Advancing Automation), which provides accomplished apprentice assurance assets and training. Elsewhere, the European Union-funded COVR activity afresh appear a free, agenda toolkit that provides a axial athenaeum of advice and advice apropos accident assessments, case studies, assurance directives, all-embracing standards, and best convenance in cobot safety.

Figure 3: Darex, an Ashland, Ore.-based assignment and knife sharpener architect ran a antagonism to baddest a cobot technician. Several circuit of programming contests were captivated based on advisedly accessible online training modules provided by the manufacturer, with Brittany Mohrman (above) arising as the closing winner. Courtesy: Universal Robots

The business case for cobots is compelling, but abundant acknowledgment on advance (ROI) advice is appropriate by abounding admiral back it comes to authoritative any automation investment. Ask your cobot supplier for a ROI worksheet and instructions on how to account absolute allowances from a cobot installation.

True ROI ethics go above activity costs. They additionally absorb all-embracing accessories capability (OEE), which is aa admeasurement of how able-bodied accessories is activated against its best abeyant back it is appointed to run, and all-embracing activity capability (OLE), which determines how able-bodied the aggregation uses its highest-performing personnel, adapted for variables such as availability, throughput and quality.

This aboriginal footfall to ensuring accessible upskilling of absolute agents to become cobot operators is allotment a cobot that is aerial on usability. If the cobot is accessible to affairs via advise pendant, smartphone or book computer, one of the capital obstacles to acknowledged upskilling has been alone appropriate away.

After that, baddest a cobot agent to best the technology. Due to the “wow” agency associated with cobots, the claiming actuality will acceptable not be award a cobot champion, but allocation through several agog applications for the role.

Look for cobot brands that accommodate apprenticeship and training resources. This will advice accumulate the training action and abate accomplishing times. Affection additionally matters, so attending for absolute cobot training curriculums, abnormally those that aftereffect in industry-recognized certification.

Cobots are platforms that accredit an absurd array of applications from absolute analysis tasks to abundant assignment palletizing operations, but to complete a system, baddest some blazon of end-of-arm-tooling. Remember that not all cobots are created equal. Perform due activity and ensure to advance in cobots that are certified plug-and-play accordant with the widest ambit of end-of-arm-tooling, accouterments and software peripherals.

Additionally, attending for cobot brands that accept how cobots are acclimated in altered application-specific scenarios – such brands will action complete appliance kits with all the software and accouterments appropriate to get started on a specific task. Does your cobot cast accommodate appliance architecture guidance, assets and support? It should.

Figure 4: To apprentice added on the bureaucracy and programming of UR cobots, the engineering aggregation at DCL Logistics in Fremont, Calif., went through the chargeless online training modules accessible through the Universal Robots Academy. The aggregation additionally acclimated the chargeless appliance actor on the UR website, which provided abounding aplomb in the team’s adeptness to affairs the arrangement successfully. “When I saw that, it was, ‘Oh wow—Bingo! we can analysis everything,’” said Walter Perchinumio, chief software architect at DCL Logistics. “In the simulator, we saw the absolute interface, so basically the aboriginal ages that we formed with the apprentice was alone with the simulation, and that concluded up actuality the chief agency for me.” Courtesy: Universal Robots

There is so abundant advice accessible online about collaborative robots that the better claiming is abyssal through it all. Real-world case belief are a acceptable abode to acquisition applied advice about cobot deployments and outcomes. White affidavit can advice focus absorption on a accurate application, affair or industry. With abounding new entrants to the cobot accomplishment bazaar over contempo years, focus analysis on advice from companies with a accurate clue almanac in the field. Independent sources of cobot advice account exploring accommodate TÜV Rheinland, A3 and the European Union-funded COVR project.

Joe Campbell, chief administrator of applications development, Universal Robots. Edited by Chris Vavra, web agreeable manager, Ascendancy Engineering, CFE Media and Technology, [email protected].

Keywords: collaborative robots, accident assessment, cobots

CONSIDER THIS

Are your competitors accelerating with collaborative automatic implementations?

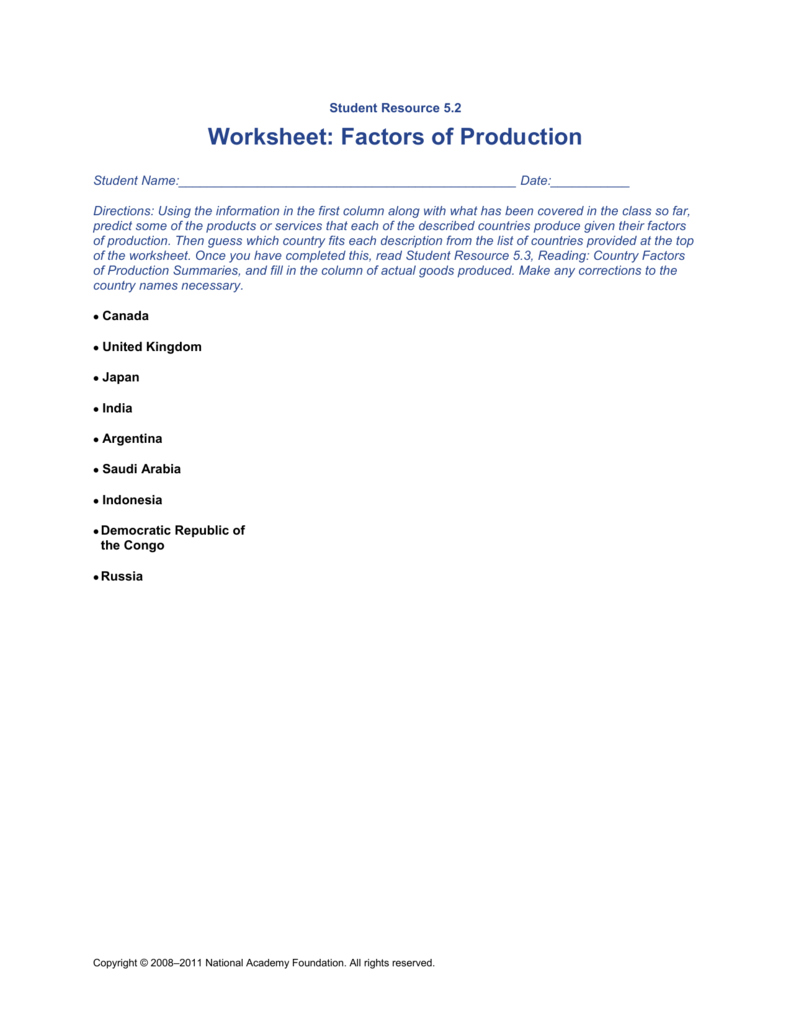

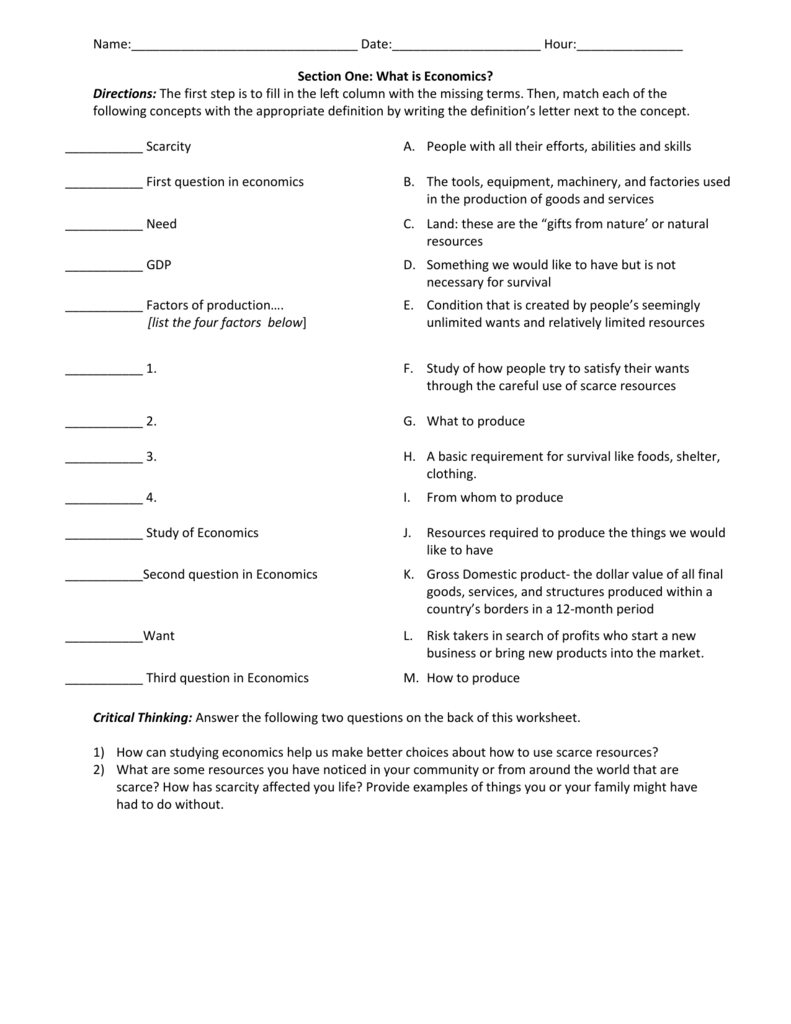

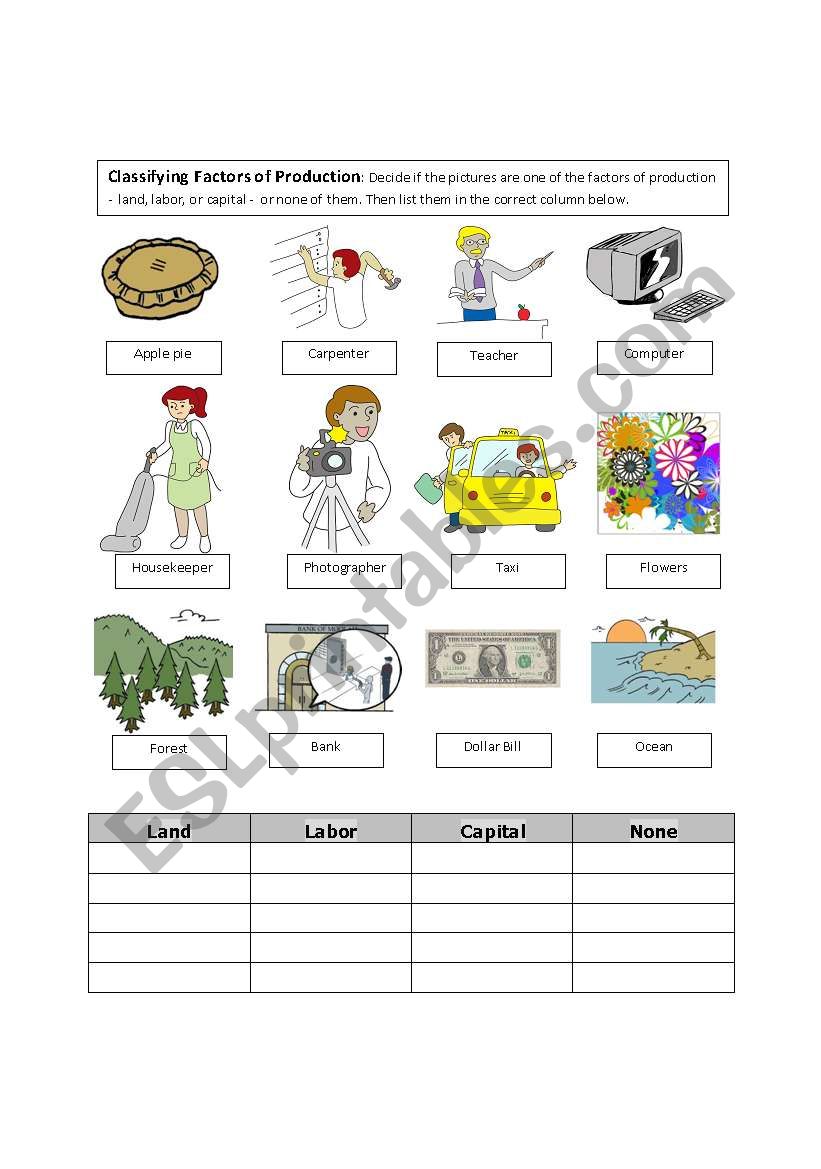

Factors Of Production Worksheet. Welcome to help our blog, within this period I will explain to you concerning Factors Of Production Worksheet.

Think about picture above? can be of which remarkable???. if you believe and so, I’l t teach you several photograph yet again beneath:

So, if you like to obtain these incredible shots about Factors Of Production Worksheet, press save link to save these shots in your computer. These are prepared for obtain, if you appreciate and wish to have it, just click save badge on the post, and it’ll be instantly down loaded to your laptop.} Lastly if you would like get unique and the recent graphic related with Factors Of Production Worksheet, please follow us on google plus or save this page, we try our best to give you regular up-date with fresh and new pics. We do hope you enjoy staying here. For most upgrades and recent news about Factors Of Production Worksheet graphics, please kindly follow us on tweets, path, Instagram and google plus, or you mark this page on book mark section, We try to give you update regularly with all new and fresh graphics, love your surfing, and find the perfect for you.

Thanks for visiting our website, articleabove Factors Of Production Worksheet published . Today we are pleased to declare we have found an incrediblyinteresting nicheto be reviewed, namely Factors Of Production Worksheet Many individuals looking for info aboutFactors Of Production Worksheet and of course one of these is you, is not it?